POWDER DOSER

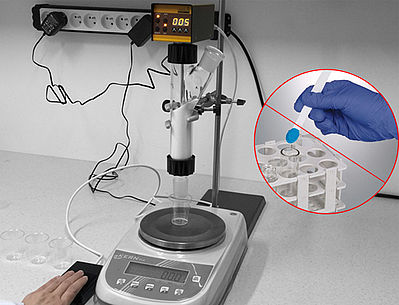

The LAMBDA DOSER & HI-DOSER powder feeder is a unique programmable powder pump for free-flowing solid substances. For safe dosing of chemicals in your lab. Unique powder pump for free-flowing solid substances.

It allows automated continuous dispensing or intermittent addition (with pauses) of powders, powdery and crystalline substances without a spoon.The powder dispensers with an optional foot-switch can be used to dispense the powder in portions in media preparation, monitoring and screening.The powder dispenser consists of a dosing unit coupled to a digitally controlled stepping motor, allowing the constant and reproducible dosing of solids.

As the DOSER / HI-DOSER powder feeder offers different control options, it can also be used in automatically controlled processes.Automation of the powder dispensing process in the life sciences, pharmaceutical or analytical laboratory can be done with the programmable powder dosing pump as it reduces human error, risk of spillage and conforms to laboratory safety standards.

DOWNLOAD CATALOG

The powder dosing instruments : DOSER 0.2 L, DOSER 1 L, DOSER 3 L, HI-DOSER 1 L, HI-DOSER 3 L

Dosing Rate of Powder Dispenser:

The dosing speed can be set directly on the control display of the powder feeder or remotely from 0–999 speed range for precise and reproducible solid flow rate.

The powder dosing rate depends mainly on the powder properties.

For example, the dosing rate range of NaCl at our laboratory conditions:

- LAMBDA DOSER: 50 mg/min to 50 g/min

- LAMBDA HI-DOSER, slow mode*: 60 mg/min to 60 g/min

- LAMBDA HI-DOSER, fast mode*: 250 mg/min to 250 g/min

*On the HI-DOSER unit, you can work with either slow or fast mode at a time, based on your flow rate requirement.

Volume of Storage Vessels:

DOSER and HI-DOSER powder feeders are supplied with the following glass vessels:

- Approx. 200 ml or 0.2 L glass vessel

Corresponds to 250 g NaCl, 200 g NaHCO3 or 150 g sucrose. This capacity is optimal for most laboratory applications. - 1 L glass vessel (approx. 1 L volume)

- 3 L glass vessel (approx. 3 L volume)

The glass vessels are interchangeable. For larger volumes, the side neck in the glass vessel allows filling during operation.

Remote Control of Powder Pump:

The whole speed range of powder dispensing can be remotely controlled by applying a voltage of 0-10V. Switching the powder feeder on and off (ON/OFF) is controlled by an external contact or 12V signal. The RS-485 or RS-232 interface(optional) allows for enhanced PC control (variable flow rates, flow profile, etc.)

Data Storage and visualization:

The PNet PC control software is ideal for remote control of dosing units, data storage and visualization of powder dosing.

You can connect up to 6 powder dispensers via RS-485 interface and cables to USB or serial port of the computer, without having to purchase additional software licenses for the additional laboratory equipment.

The PNet software allows to create dosing profile, record data for analysis or comparison, visualize real time trends and to save data to PC.

Conformity to Safety in Lab:

The powder dispensers LAMBDA DOSER and LAMBDA HI-DOSER allows a safe and reproducible dosing of hazardous chemicals in the lab and conforms to modern safety rules. To protect the laboratory technician or researcher or student, the powder dosing device can also be controlled remotely. The hermetic construction of the DOSER and HI-DOSER allows safe handling of dangerous and toxic solid substances.

Several seals make the DOSER air-tight and it can be used with a slight over- or under-pressure. If the powder sample has to be protected from agglomeration or reaction with air humidity, the glass vessel can be purged with inert gas or dry air using the supplied gassing plug.

If the process needs to be protected from the risk of breakage, you can also order the glass vessels with a silicone coating(outside). All parts in contact with the powdery substances are made of chemically resistant materials.

Quality Standards for Powder Dosing:

LAMBDA DOSER / HI-DOSER powder feeders are recommended for high quality standard of powder dosing in the laboratory. In addition to the digital setting and precise dosing mechanism, the automatic recording of dosing data makes it an optimal choice to dispense powders under GMP and GLP.

Applications:

The time consuming conventional manual dispensing can now be replaced quickly and simply by the powder pump:

The time consuming conventional manual dispensing can now be replaced quickly and simply by the powder pump:

Powder dispensing with a click instead of a spatula saves time in media preparation, monitoring and screening: Hundreds of portions of the same substance (media components or active ingredients) can be prepared in different recipients easily with a click.